PRODUCT SEARCH

Enquiries

If you have any questions about products featured on this site, or on products that you cannot find on this site, please contact us and we will be happy to assist you in any way that we can. We have a team of technical sales specialists who are waiting to hear from you!

Contact UsHome Life Science Solutions Bioreactors

Bioreactors

Pilot and Industrial Fermenters and Bioreactors

We supply Solaris Biotech’s range of Pilot and Industrial fermenters and bioreactors in Ireland. The range is fully customisable, cGMP certifiable, highly flexible and with customised applications that are personalised to the needs of our customers. We work closely with existing and potential clients to ensure that the finished product meets all of their immediate and future requirements.

Our Solaris Biotech line includes various finishing, agitation (mixing), thermoregulation loops, and SIP/CIP configurations, as well as a variety of measurement and control options such as pH, DO, cell density, gas mixing and gas analysers.

Standard range of pilot units:

The M series includes standard SIP fermenters/bioreactors in a total of 6 different capacities from 30 to 200 litres, with a wide range of options and accessories allowing for a high level of customisation.

Features and benefits:

6 different volumes: 30 L, 50 L, 75 L, 100 L, 150 L, 200 L

3:1 H/D ratio

Parts in contact with the culture AISI 316 L, other parts AISI 304

Finishing: mirror polished (internal and external)

Compact design

Double jacket (side/bottom), for improved heat transfer efficiency and optimal temperature control

Bacteria (Toroid sparger, Rushton impellers) and cell cultures (Sintered sparger, Marine impellers) configurations available

Welded baffles

Selection of measurement and control options for cell cultures and aerobic/anaerobic microbial fermentations, including temperature, pH, dO2, dCO2, redox, antifoam, level, conductivity, weight, cell density (total cells, viable cells)

Modbus digital sensors

Suitable for batch, fed-batch, and continuous processes

Stainless-steel industrial PCS LEM_2, with a selectable number of peristaltic pumps, choosing between Watson Marlow WM 114, WM 313, and WM 520

Powerful and accurate (1 RPM) brushless motor, mounted on top

Different gas mixing strategies with a selectable number of TMFCs or solenoid valves, for air, O2, CO2 and N2

Standard configuration includes SALAS (Solaris Sterile Liquid Addition System)

Option to add up to 2 steam bridges (re-sterilizable diaphragm valves for inoculum/feedings), with manual or automatic sterilization control

Non-SIP sampling and harvest valves are included in the standard configuration with optional Steam SIP lines. Manual or automatic sterilization

Tri-Clamp stainless steel piping

Single mechanical seal. Double mechanical seal, with automatic lubrication though steam condensate loop available as an option

Thermoregulation loop consisting of two heat exchangers and recirculating pump

Separate drains: cooling water return, condense drain to waste, hot condense return.

Gravimetric flow control (option): feed rates controlled through weight measurement.

CIP system options: number of removable spray balls or integrated system (recirculating pump + number of removable spray balls + software automation). Number of spray balls depending on vessel volume.Optional empty vessel sterilization.

- Download M Series Brochure

The S - I SERIES, SIP and CIP Customisable Pilot and Industrial Scale Fermenters/ Bioreactors include highly automated pilot-industrial fermenters and bioreactors with capacities ranging from 50 up to 30,000 litres (S series 5 – 200 L; I series 300 – 30,000 L). These fermenter units are tailor-made and can be fully customised to meet the needs of the customer.

The systems can be equipped with a diverse range of measurement and controls. The S and I series meet and exceed both sterility and cleanliness requirements, complying with even the most stringent pharmaceutical industry requirements. All vessels are designed, fabricated, inspected, documented, and tested following European PED or ASME design standards.

Volumes range from 50 Litres up to 30,000 Litres and are available for almost every volume you require.

Features and benefits:

Top-quality stainless steel with excellent finishing and cutting-edge technology insulated vessels, with the possibility of passivation

Various H/D ratios

Variety of finishing such as mirror polish, scotchbrite, electropolishing, etc.

Different types of agitation: top-bottom, single or double mechanical seal with lubrication loop, magnetic stirrer

Different kinds of thermoregulation loops ranging from basic to completely closed

Microbial (aerobic, anaerobic) and cell cultures configurations available

Suitable for batch, fed-batch, and continuous processes

Several gas mixing strategies with a configurable number of rotameters, TMFCs or solenoid valves, for air, O2 , CO2 and N2

Temperature, pH, dO2, dCO2, redox, antifoam, level, conductivity, weight, cell density (total cells, viable cells) and other parameters can be measured and regulated

Digital Modbus sensors

Stainless-steel industrial PCS LEM_2, with a selectable number and type of peristaltic pumps

cGMP certifiable

Easy access to service lines, allowing for fast maintenance

A wide range of ancillary services (feeding tanks, mixing tanks, harvest tanks, etc.) are available, and these can be combined with tanks CIP/SIP systems, centrifuges, filtration systems, and other ancillary equipment to provide a turn-key solution (see Bioprocessing Equipment).

- Download S and I Series Brochure

Automation and Software:

The M, S & I series are controlled by the ground-breaking SCADA software LEONARDO 3.0: a smart and user-friendly controller built to provide a high degree of automatic fermentation/cultivation process management.

A 24” coloured touch screen industrial HMI is included with the equipment supply

Data extraction in .csv format

QR code scanning or dedicated portal for remote access via PC, tablet, or smartphone

After sale assistance via remote control

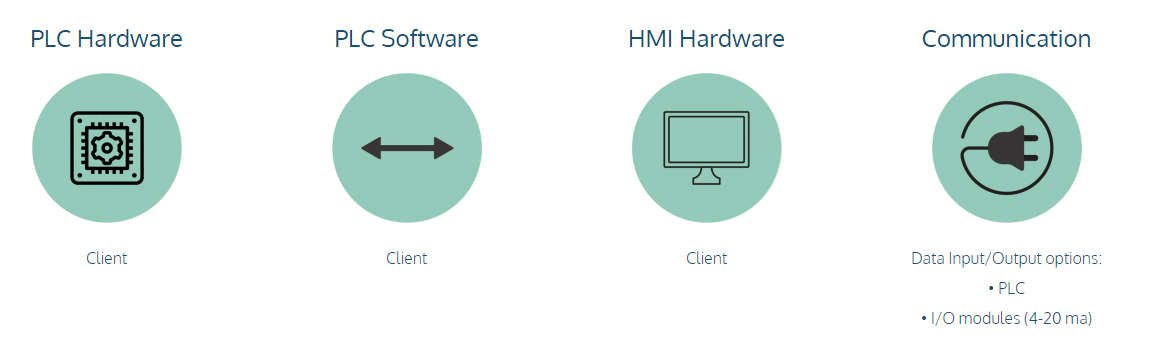

Our PLC hardware is based on the industry standard Siemens S7 controller series, which allows for simple programming and customisation.

We offer a flexible scope of control strategies for our pilot and industrial solutions that can be completely integrated into the clients process.

Data Analysis

Our data analysis interface allows you to exchange performance data with any MySQL software allowing you to:

Exchange process parameters and data in real-time

Software such as Lucullus, Excel, Python, and any MySQL client are all compatible

Bioreactors1 items found

|

Bioprocessing Equipment

Additional systems are needed for Pilot and Industrial processes to perform properly, and we have the appropriate technology to assist you. Enquire about this product |

View details |